Optical Sensors hot metal detector Proxintron VietNam ANS VietNam

Xuất sứ: Germany

Nhà cung cấp: Proxitron VietNam ANS VietNam

Hãng sản xuất: Proxitron

Hot Metal Detector / Temperature switch

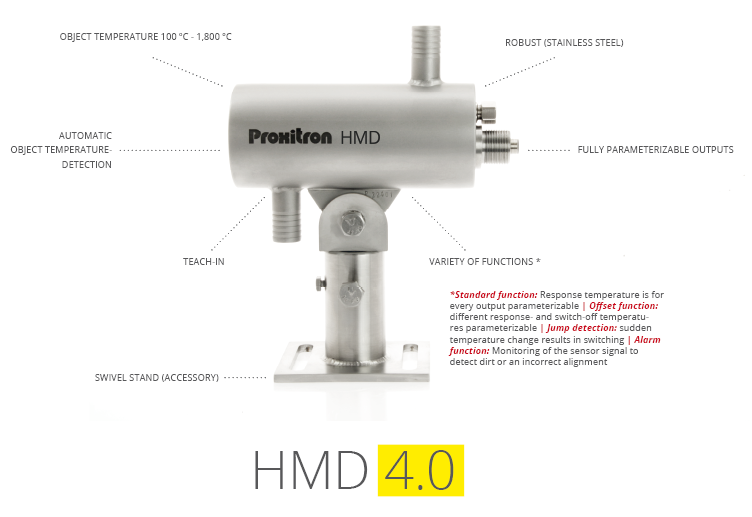

Proxitron Hot Metal Detectors (HMDs) detect the infrared radiation which is emitted by hot material. When the material temperature exceeds or falls below a specific threshold (response temperature), they provide a switching signal; seen from this perspective, they are often called also Temperature Switches. A response time of less than half a millisecond allows the supervision of even very quick manufacturing processes in steelworks, rolling millls or in the forging industry.

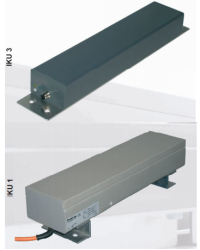

Temperature Switches – are characterized by their extremely robust and maintenance-free housing. They withstand for years the harshest working conditions such as water vapour, dust, vibrations, radiation heat, and ambient temperatures up to 600°C.

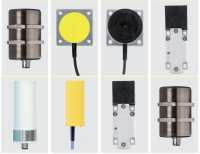

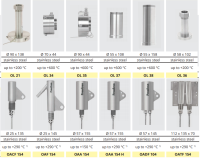

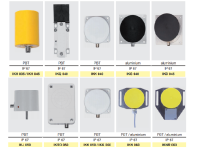

Proxitron offer a large variety of infrared sensors. By selecting the basic criteria such as ambient temperature, response temperature, supply voltage, connection and field of view, you can choose the perfect sensor for your application by using our sensor selector.

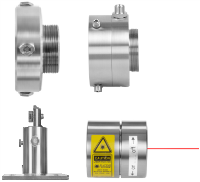

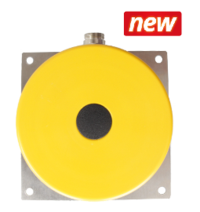

Our newest series of Hot Metal Detectors - the OX series – provides a previously unknown range of functions in only one device. The sensors not only can be parameterized easily due to the Teach-In function, furthermore we equipped the sensors with a lot more smart functions. Besides the standard function (fully free parameterizable outputs), you can also choose the offset function (different response- and switch-off temperatures are parameterizable). An alarm function supplies information of unsecure operating states and the jump function can react - independently of a fixed response temperature - to sudden temperature changes of the application. Equipped with a comfortable software interface, the sensors of the OX series fulfill the requests of the industry 4.0.

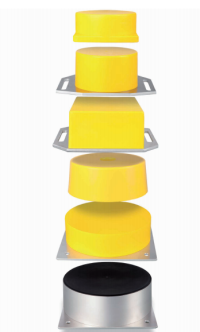

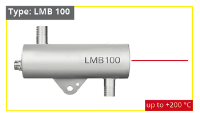

We remain loyal to our concept of facing high temperature environments always with the appropriate design. If the ambient temperature is not exceeding 75°C, a simple and cheap compact housing is enough. For ambient temperatures reaching 200°C we recommend the use of a compact equipment with water-cooling, and for increasingly higher temperatures, for example up to 290°C, a device with fibre optic cable and separate optic.

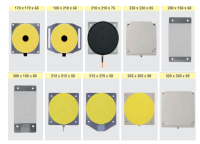

The ambient conditions in steelworks, rolling mills, wire plants and foundries poses a challenge that we can solve together. Dust, scales, soot, rolling emulsions, vapour and significant mechanical stress: our accessories range is an adequate task for our accessories.

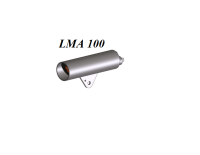

This includes an extensive and almost indestructible protection system for the cables of the temperature switches as well as tailored air purge units to protect optics from dust, scales and water spray. For the alignment, mounting and field of view-reduction we offer accessories made of stainless steel, perfectly tailored to our sensors. Extremely robust and adjusted to your requirements.

Specific characteristics

- Extremely robust

- Shock and vibration resistant

- Wear and maintenance free

- Very quick response times

- Adjustable response temperature

- For ambient temperatures up to +600 °C

- Great selection of models and connection versions

- Diverse electrical outputs

- Stainless steel housing

- Complete range of accessories

Application areas

- Wire processing

- Hot rolling

- Pipe production

- Crude steel production

- Sheet metal working

- Glass production

- Pressing

- Steel industry

- Plant construction and mechanical engineering

- Automotive industry

- Engine manufacture

- Foundries

- Forging